Expansion

der

industriellen

Befülltechnik

Expansion

der

industriellen

Befülltechnik

Expansion der industriellen Befülltechnik

Das Fibreblow-System ist erstklassige Anlagentechnik für gleichmäßige und setzungssichere Einblasresultate in Dach-, Wand- und Deckenelementen. Es ist leistungsstark, benutzerfreundlich und ermöglicht eine nahtlose Skalierung von teil- bis vollautomatischen Prozessen, die Integration in bestehende Fertigungsstraßen und die Anbindung an software-gesteuerte Brücken- oder Robotersysteme.

Automation

Bestens integrierbar in automatisierte Fertigungsprozesse - von der Bemessung bis zur Datenerfassung

Qualität

Minimale Hügelbildung und maximale Setzungssicherheit dank patentierter Plattenkonstruktion

Leistung

Hoher Materialdurchsatz und schnelles Befüllen aller Gefache mithilfe optimal vorbereiteter Fasern

Gesundheit

Umwelt- und gesundheitsfreundlich durch staubarme Befülltechnik und gekapselte Einblasplatte

Handhabung

Benutzerfreundlich durch flexible Steuerung über integriertes Bedienfeld, mobiles Tablet oder Fernbedienung

Fibreblow Premium Plate

Werksbefüllung mit Holzfaser, Zellulose, Glaswolle, etc.

Die Fibreblow Plate ist eine Einblasplatte zur industriellen Befüllung von Wand-, Dach- und Deckenelementen mit losen Dämmstoffen. In Kombination mit dem Fibreblow Feeder Lift und dem Fibreblow Feeder Drop, sorgt sie für schnelle und gleichmäßige Gefachbefüllung mit optimal vorbereiteten Fasern. Die patentierte Stutzenkonstruktion gewährleistet minimale Hügelbildung, optimale Eckbefüllung und höchste Setzungssicherheit. Mithilfe der Software sind die nahtlose Integration in bestehende Fertigungsprozesse sowie kurze Rüstzeiten beim Dämmstoffwechsel sichergestellt.

Pluspunkt: Leistung

- ▸Minimale Hügelbildung: ±10mm

- ▸Materialdurchsatz: 1200kg/h bei 20cm Dämmstärke (Holzfaser)

- ▸Maximale Setzungssicherheit

- ▸Integrierter Verstärker

- ▸Automatisierte Befüllung über manuell anwählbare Stutzen

- ▸Positionlaser zum exakten Platzieren der Platte

- ▸Staubarme Befüllung und gekapselte Einblasplatte

- ▸Lasergestütztes Positionieren z. B. mit Hallen- oder Portalkran

- ▸Software-Konfiguration für zwei Dämmstoffe (weitere optional)

- ▸Fachgeometrie unabhängige gleichmäßige Dichteverteilung

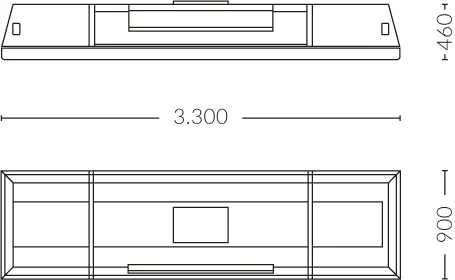

Technische Daten

| Abmessungen (LxBxH) | 3300x900x460mm (P6 ohne Aufhängung) |

| Gewicht | ca. 480kg |

| Elektrischer Anschluss | 400V/50Hz/16A |

| Materialdurchsatz | max. 1200kg/h (Holzfaser), 2000kg/h (Zellulose, Glaswolle) |

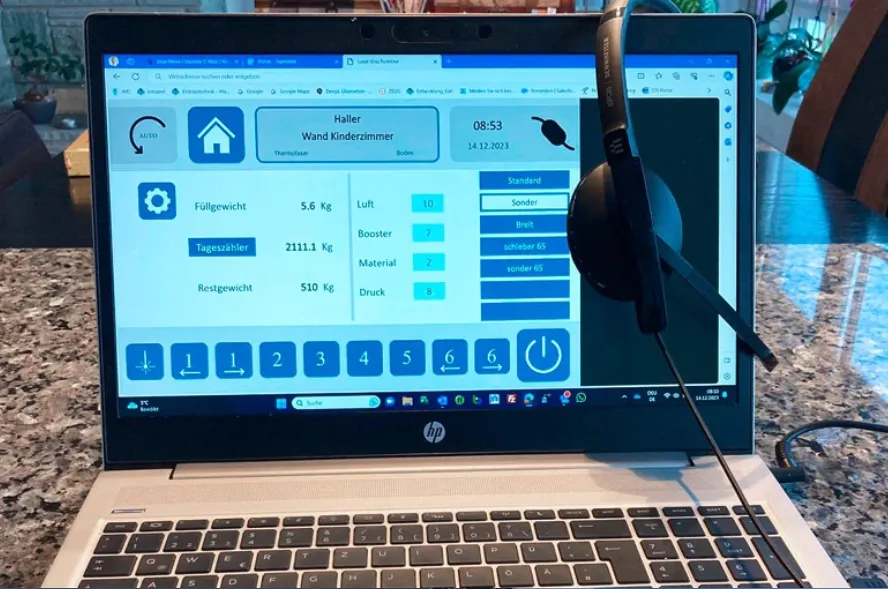

| Steuerung | Touch screen, Tablet (mobil) |

Fibreblow

Modulare Technik für serielle Sanierung und industrielle Vorfertigung

Automatisierte Prozesse, effiziente Verarbeitung und Wirtschaftlichkeit: X-Floc Fibreblow Premium steht für erstklassige Systemtechnik im Bereich industrielle Vorfertigung und energieeffiziente Renovierung.

Fibreblow

Modulare Technik für serielle Sanierung und industrielle Vorfertigung

Automatisierte Prozesse, effiziente Verarbeitung und Wirtschaftlichkeit: X-Floc Fibreblow Premium steht für erstklassige Systemtechnik im Bereich industrielle Vorfertigung und energieeffiziente Renovierung.

KONTAKTIEREN SIE UNS DIREKTFibreblow Premium Feeder Lift

Optimale Faseraufbereitung und Materialzuführung

Der Fibreblow Feeder Lift mit integriertem Einblasmodul ist der perfekte Großballenzerkleinerer für die automatisierte und schnelle Verarbeitung von losen Dämmstoffen. Er sorgt für eine besonders schonende Feinauflösung der einzublasenden Fasern. Holzfaser, Zellulose und Glaswolle können mit hoher Geschwindigkeit der Premium Plate zugeführt und in die Rahmenelemente eingeblasen werden. Wiegezellen und passende Messelektronik ermöglichen die kontinuierliche Überwachung der Einblasqualität und ggf. schnelle Anpassung der Maschineneinstellungen.

Pluspunkt: Leistung

- ›First in – First out Prinzip für faserschonendes Auflösen ohne Scherbeanspruchung

- ›Integriertes Einblasmodul für maximalen Materialdurchsatz (1200kg/h mit Holzfaser, 2000kg/h mit Zellulose und Glaswolle)

- ›Vom Ballenbrechen bis zur Faserauflösung optimale Faservorbehandlung

- ›Integriertes Wiegesystem für präzise Prozesssteuerung

- ›Schnelles und einfaches Beladen und Reinigen

- ›Materialwechsel beansprucht wenig Zeit

- ›Fernwartungssoftware zum Monitoring und zur Diagnose

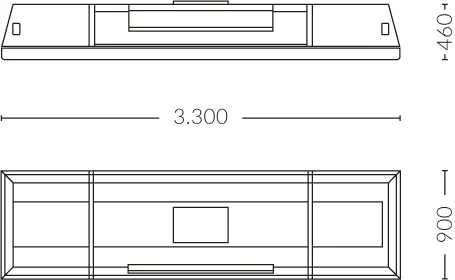

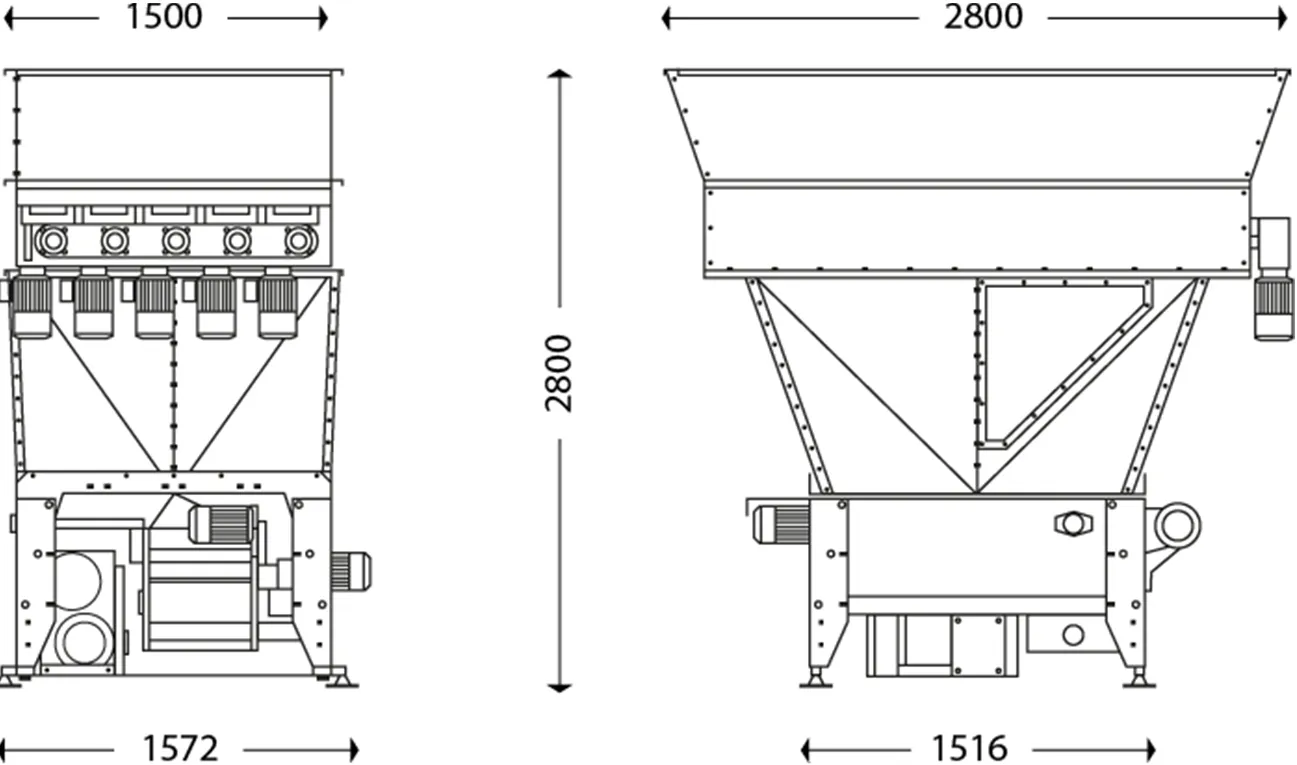

Technische Daten

| Abmessungen (LxBxH) | 2445x1800x3402mm |

| Gewicht | ca. 2065kg |

| Elektrischer Anschluss | 400V/50Hz/32A |

| Vorratsvolumen | ca. 2,5m³ |

| Steuerung | Touch screen, Tablet (mobil) |

Optionen Fibreblow Premium

Fibreblow

Modulare Technik für serielle Sanierung und industrielle Vorfertigung

Automatisierte Prozesse, effiziente Verarbeitung und Wirtschaftlichkeit: X-Floc Fibreblow Premium steht für erstklassige Systemtechnik im Bereich industrielle Vorfertigung und energieeffiziente Renovierung.

Fibreblow

Modulare Technik für serielle Sanierung und industrielle Vorfertigung

Automatisierte Prozesse, effiziente Verarbeitung und Wirtschaftlichkeit: X-Floc Fibreblow Premium steht für erstklassige Systemtechnik im Bereich industrielle Vorfertigung und energieeffiziente Renovierung.

KONTAKTIEREN SIE UNS DIREKTFibreblow Premium Feeder Drop

Kundenspezifisch wählbares Füllvolumen

Mehrere kleine Ballen oder gleich drei Großballen: Der Premium Feeder Drop mit integriertem Einblasmodul ist die perfekte Lösung, um optimal vorbereiteten Dämmstoff unterbrechungsfrei einer Premium Plate zuzuführen. Groß- wie Kleinballen werden zuvor schonend von vier waagerechten, einzeln angetriebenen Zahnwalzen aufgebrochen und zerkleinert. Der Feeder Drop zeichnet sich durch variable Anpassung des Füllvolumens (Standard: 6m³) an die jeweiligen Bedürfnisse aus - mittels optionalem Metallrahmenaufsatz oder durch Einbau in individuelle Materialzufuhrlösungen.

Pluspunkt: Leistung

- ›First in – First out Prinzip für faserschonendes Auflösen ohne Scherbeanspruchung

- ›Einblasmodul für maximalen Materialdurchsatz (1200kg/h mit Holzfaser, 2000kg/h mit Zellulose und Glaswolle)

- ›Vom Ballenbrechen bis zur Faserauflösung optimale Faservorbehandlung

- ›Integrierte Wiegezellen und Messelektronik für präzise Prozesssteuerung

- ›Schnelles und einfaches Beladen und Reinigen

- ›Fernwartungssoftware zum Monitoring und zur Diagnose

- ›Kundenspezifisch wählbares Füllvolumen (Option: Metallrahmenaufsatz)

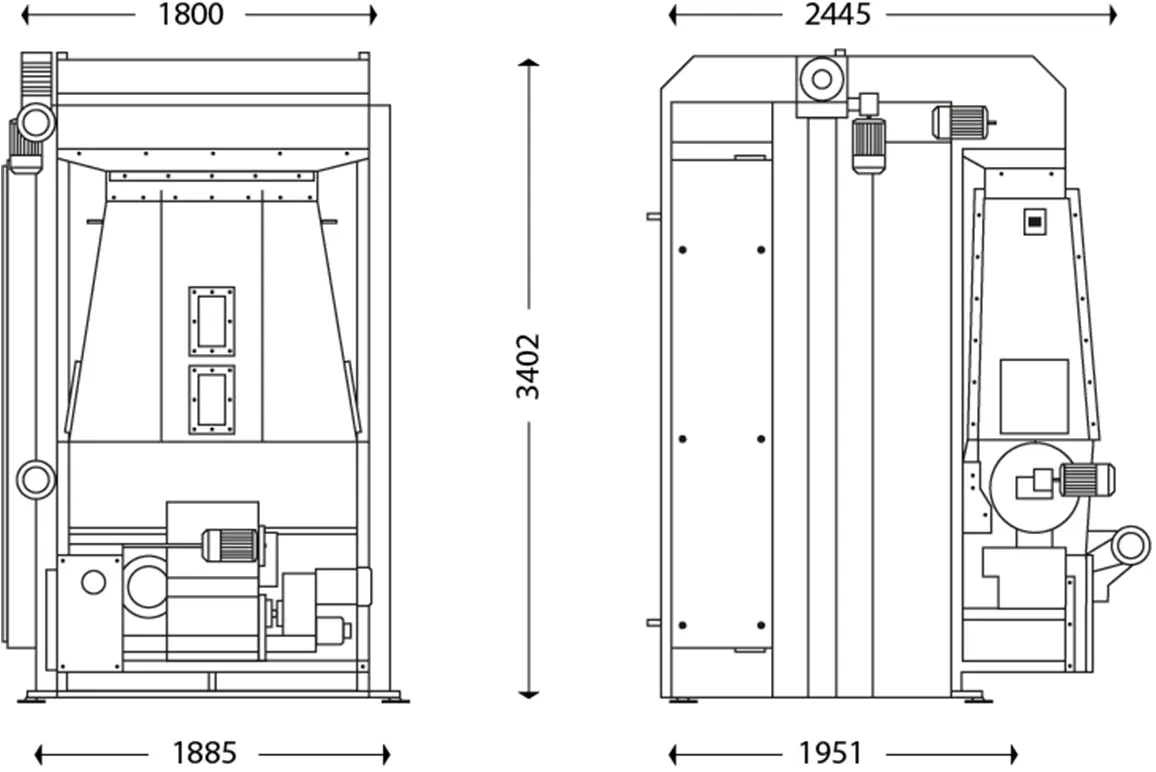

Technische Daten

| Abmessungen (LxBxH) | 2800x1500x2800mm |

| Gewicht | ca. 1465kg |

| Elektrischer Anschluss | 400V/50Hz/32A |

| Füllvolumen | 6m³ (Standard) |

| Steuerung | Touch screen, Tablet (mobil) |

Optionen Fireblow Premium

Impressionen

Einfache Integration

in vorhandene Fertigungsstraßen und software-gesteuerte Brücken- und Robotersysteme in der Praxis erprobt

Patentierte Einblasstutzen

sorgen für minimale Hügelbildung (±10mm), höchste Setzungsicherheit und ein homogenes Einblasbild

Fernwartung

Überwachung und Diagnose erfolgt mittels spezieller Software von einen entfernten Standort

Produktbroschüre

Fordern Sie die Produktbroschüre mit weiteren technischen Details als PDF an

PDF ANFORDERNTechnische Beratung

Bei Fragen zum Fibreblow-System hilft Ihnen unser Expertenteam gerne weiter

BERATUNG ANFRAGENKompetente Beratung und Support

Unser Expertenteam beantwortet gerne Ihre Fragen zum Fibreblow-System und hilft Ihnen, die perfekte Lösung für Ihre Produktanforderung zu finden.

Lassen Sie uns über Ihr Projekt sprechen

Sind Sie bereit zur Effizienzsteigerung? Kontaktieren Sie unser Sales-Team für Preise, technische Details und Lösungen.

KONTAKTIEREN